SolutionsComplete erosion & corrosion servicesAt PIP360, we analyze the effect of operational conditions and chemical reactions on site infrastructure to provide asset integrity teams with the tools they need to define and implement proactive and effective Predictive Maintenance Management programs. |

SOLUTIONS

Advancing products, processes and solutions

for erosion & corrosion asset integrity management.

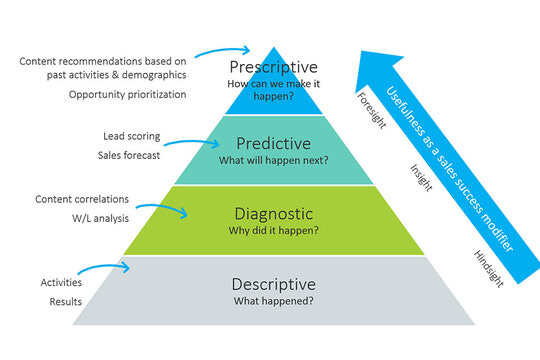

Move towards creating measurable value in your maintenance planning by extending the lifecycle of your assets with predictive and prescriptive models.

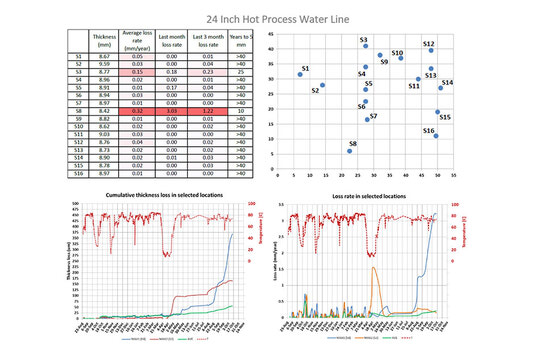

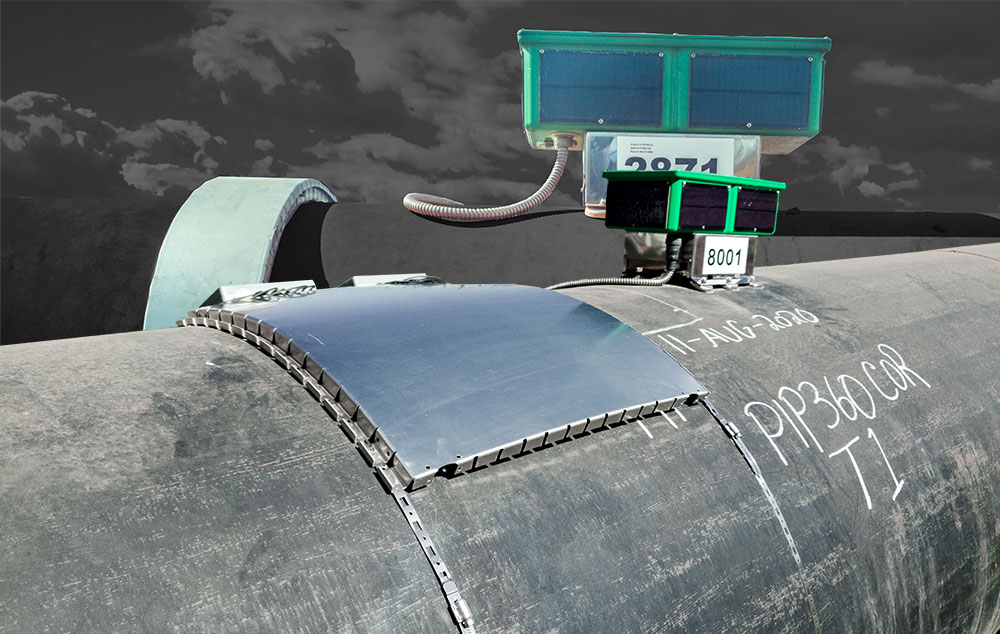

Detailed weekly or monthly reports are generated from wirelessly collected data across sensor arrays, providing valuable insights into optimal pipe rotations, angles, and replacements based on EOL calculations.

Detailed weekly reports are generated wirelessly across sensor arrays, providing valuable insights into optimal pipe rotations, angles, and replacements based on EOL calculations.

Operating conditions and pipeline lengths affect erosion and corrosion. PIP360 Inc. utilizes the PIP360 instruments with 24 sensors mounted for circumferentially to collect data for analysis. Additionally spot sensor measurements are taken along leading.

Our erosion and corrosion implementations are able to generate substantial ROI by providing a complete analysis and prescriptive maintenance model that adds verifiable value to your asset management programs.

A comparison of Maintenance Strategies is shown below:

Reactive MaintenanceFix it when it breaks - Know what happened.

|

Preventative

|

|||||

|

PROS

|

CONS

|

Predictive

Maintenance

Use data & analysis to predict breakage - Know what will happen.

|

PROS

|

CONS

|

The benefits of moving to a predictive model are known, and PIP360 offers a complete set of services to get to that stage. The industry best practice of Predictive Maintenance Management cannot be achieved with Manual Ultrasonic Testing (MUT) because of the data variability in MUT and long periods between surveys.

Prescriptive Maintenance

Uses data & analysis from Predictive model to advise on actions or decisions - Know what action to take and when.

|

PROS

|

CONS

|

The benefits of a prescriptive model to determine actions to be taken are known. PIP360 offers a complete set of services to achieve and maximize asset integrity management. Industry best practice of Predictive Maintenance Management (PdM) cannot be achieved with Manual Ultrasonic Testing (MUT) alone, because of the data variability in MUT and long periods between surveys.

The benefits of moving to a predictive model are known, and PIP360 offers a complete set of services to get to that stage. The industry best practice of Predictive Maintenance Management cannot be achieved with Manual Ultrasonic Testing (MUT) because of the data variability in MUT and long periods between surveys.

|

|

|

|

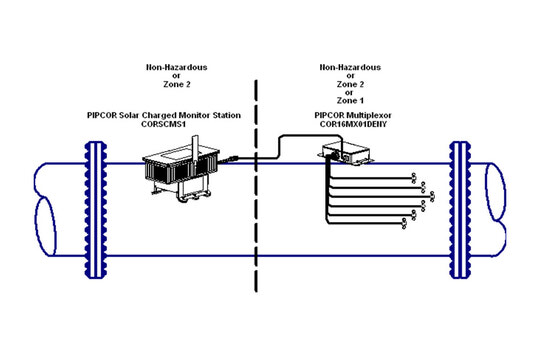

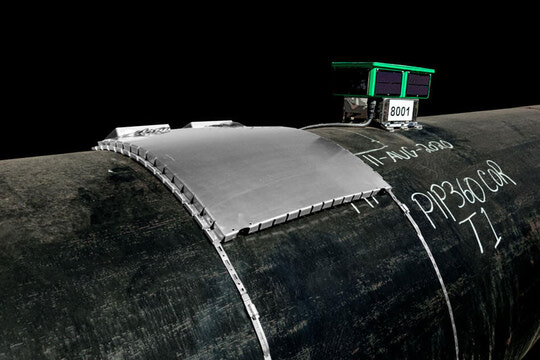

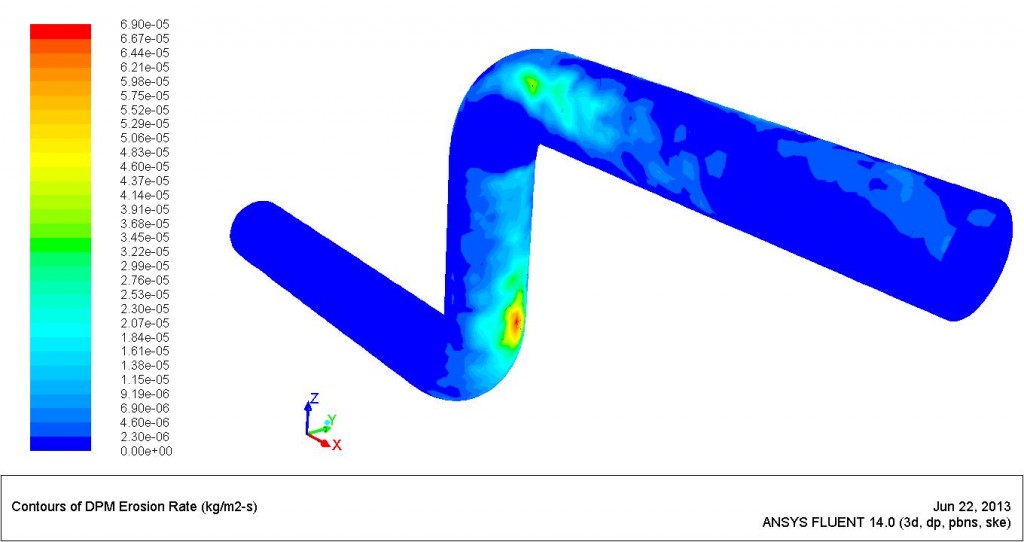

PIP360: Automated Ultrasonic Testing InstrumentsDirect measurement sensors and instruments Would you like to know if the inside of your pipe looks like this? What its minimum thickness, average metal loss, and maximum wear rate are? Then PIP360 can help. PIP360 provides direct measurement sensors and instruments used for precision monitoring of asset pipe, vessel or tank wall thickness with predicted metal loss and wear rates. We deploy instruments at known high risk or high consequence areas and—through the use of a wireless network—collect daily high-resolution thickness data that is transmitted to the PIPVIEW data center in Edmonton, Alberta for analysis and detailed reporting. |

PIPVIEW: Predictive Maintenance ManagementAnalysis and reporting is used to determine erosion and corrosion activity on a variety of transport infrastructure including pipes, pumps, and vessels. PIPVIEW helps companies manage their slurry, crude, refined or gas pipeline infrastructure to reduce hole-out risk, manage leading edge panning, increase service life, effectively schedule and plan maintenance and adjust operating conditions to achieve the maximum operational or end of life (EOL) targets for each asset. |

|

PIP360 and PIPVIEW provide actionable erosion and corrosion information to support predictive maintenance management and reduce risk to plant, people, and the environment.

|

|

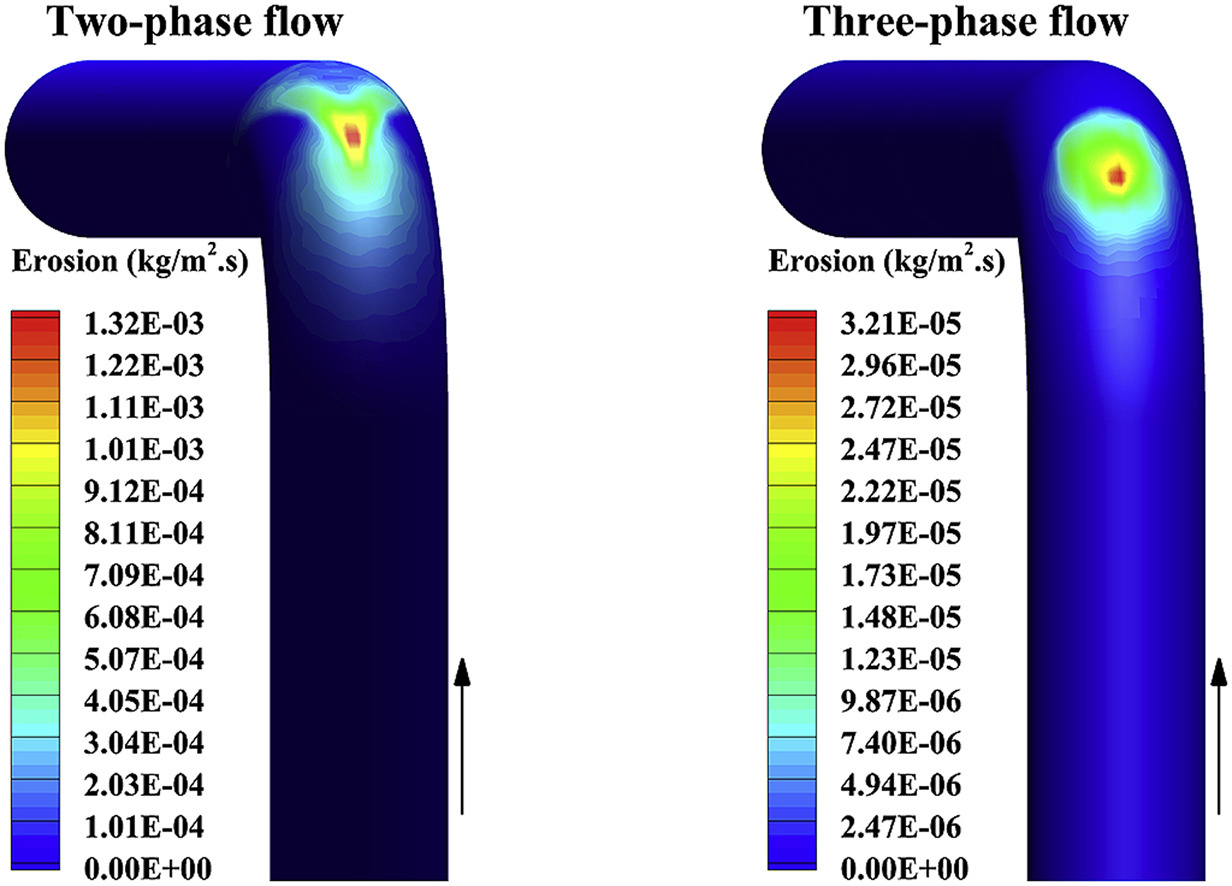

ErosionSlurries, unlike conventional hydrocarbons, are like a liquid sandpaper which erodes steel until the pipeline is worn away. Traditional Ultrasonic Testing (UT) instruments are used to manually monitor pipe thickness and determine replacement schedules. This is unreliable due to the combination of corrosion and erosion altering the wear profile over time. The PIP360 system measures actual pipe thickness data daily, enabling asset managers & engineers to safely manage their pipe’s EOL thickness by prescribing optimal rotation angles and schedules to reduce wear and maximize the pipe’s effective lifecycle. |

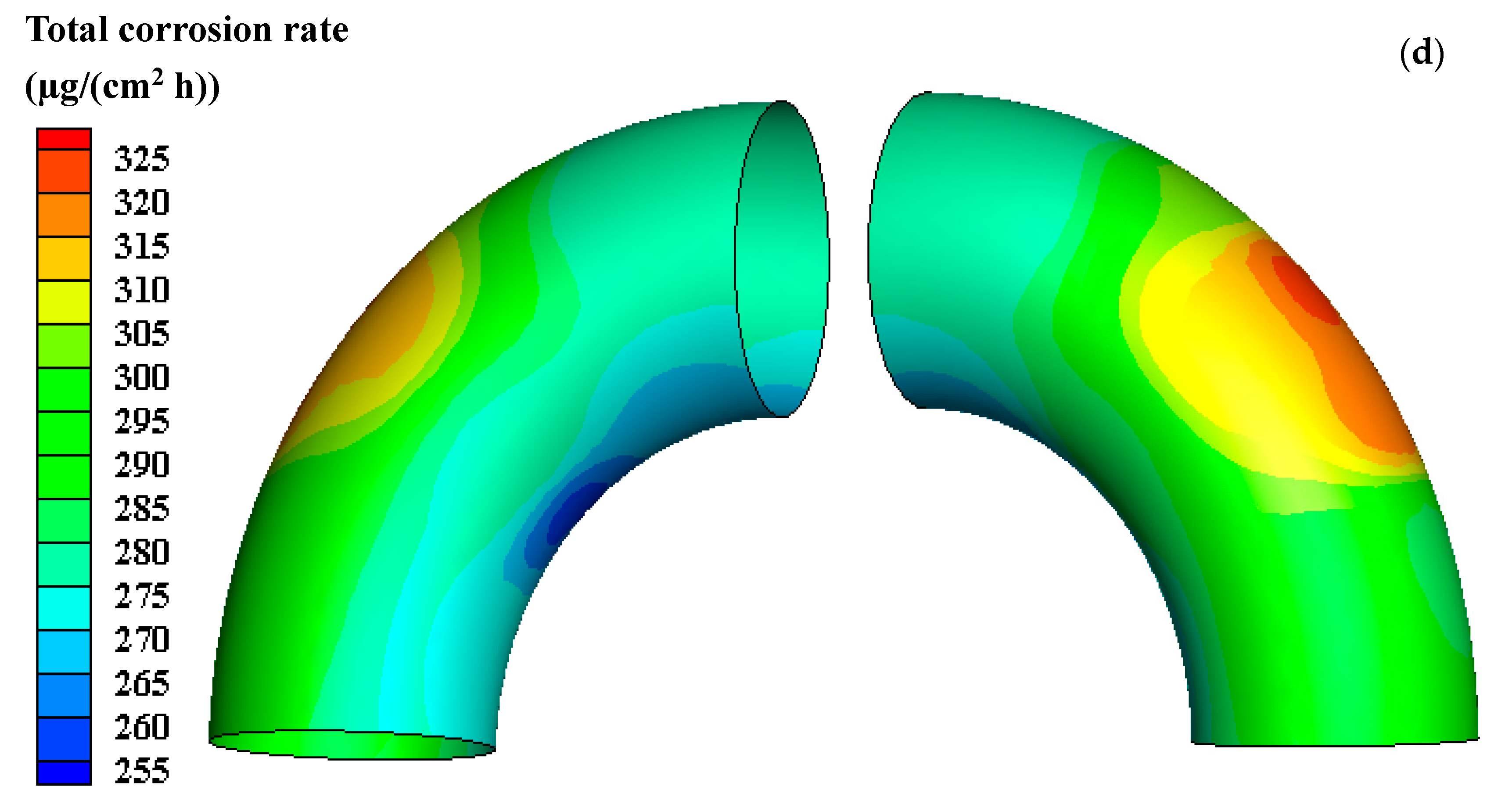

CorrosionThe highest risk of plant, utilities, upgrading, storage, and overland piping infrastructure is failure related to pitting corrosion. Pitting corrosion is a localized form of corrosion that causes the formation of cavities or holes in a pipeline much faster than the general metal loss rate. Without regular testing and analysis of the pipeline it is impossible to detect pitting. By using PIP360's systems, asset management teams receive detailed reports based on high-resolution thickness data that can identify the source of pitting and recommend mitigation to reduce or eliminate future risks. Utilizing PIPCOR statistical analysis, we are able to provide a snapshot of the failure risk allowing time to plan before a leak occurs. |

|

|

|

|

Let’s work & build something great together.

Want to see how PIP360 / PIPVIEW predictive and prescriptive maintenance management can benefit your asset integrity program?Get started today by reaching out to receive detailed information specific to your operation. |

|